A circumferential crimping tool is used for_____. – A circumferential crimping tool is used for creating secure and reliable connections in various industries. These tools employ a crimping process that involves applying pressure around the circumference of a component, resulting in a strong and durable bond. In this article, we will explore the diverse applications, benefits, and factors to consider when choosing a circumferential crimping tool.

Circumferential crimping tools are widely used in electrical, automotive, and telecommunications industries, among others. They are particularly suitable for applications requiring high precision, efficiency, and reliability. These tools offer advantages such as improved electrical conductivity, reduced risk of corrosion, and enhanced mechanical strength.

Circumferential Crimping Tools: An Overview

Circumferential crimping tools are specialized tools designed to create a uniform and secure crimp around the circumference of a connector or terminal. They are widely used in various industries, including electrical, automotive, and telecommunications, for creating reliable electrical connections.

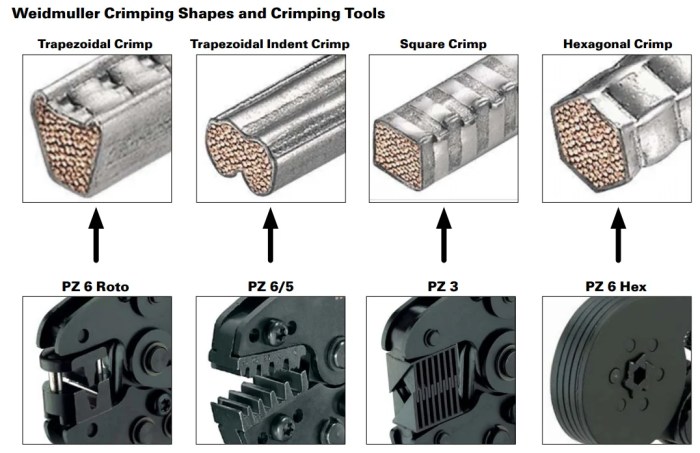

Types of Circumferential Crimping Tools

Circumferential crimping tools come in different types, each suited for specific applications. Here is a table summarizing the main types:

| Tool Name | Description | Applications |

|---|---|---|

| Manual Crimping Tool | Hand-operated tool with interchangeable dies | Small-scale electrical connections, DIY projects |

| Pneumatic Crimping Tool | Powered by compressed air, offers higher crimping force | Production environments, heavy-duty applications |

| Hydraulic Crimping Tool | Uses hydraulic pressure for maximum crimping force | Large-scale electrical installations, high-voltage applications |

| Battery-Powered Crimping Tool | Cordless and portable, ideal for field work | Telecommunications, electrical maintenance |

Applications of Circumferential Crimping Tools

Circumferential crimping tools find applications in various industries and for diverse purposes, including:

- Electrical connections: Joining wires, cables, and terminals

- Automotive: Crimping wire harnesses, connectors, and terminals

- Telecommunications: Crimping coaxial cables, fiber optic connectors

- Industrial machinery: Crimping control cables, sensors

- Aerospace: Crimping high-reliability electrical connections

Benefits of Using Circumferential Crimping Tools, A circumferential crimping tool is used for_____.

Circumferential crimping tools offer several advantages over other methods of creating electrical connections:

- Improved efficiency: Automated or semi-automated operation saves time and labor

- Reliability: Uniform crimps ensure secure and consistent connections

- Precision: Accurate crimping force and die design ensure proper connections

- Versatility: Interchangeable dies allow for a wide range of applications

Factors to Consider When Choosing a Circumferential Crimping Tool

When selecting a circumferential crimping tool, it is important to consider the following factors:

- Capacity: The maximum crimping force and wire size the tool can handle

- Crimping force: The amount of force applied to the crimp

- Ergonomic design: The comfort and ease of use of the tool

- Die availability: The range of dies available for different applications

- Durability: The longevity and reliability of the tool

Proper Usage and Maintenance of Circumferential Crimping Tools

Proper usage and maintenance of circumferential crimping tools are crucial for safety and optimal performance. Here are some guidelines:

- Use the correct die for the wire size and type

- Calibrate the tool regularly to ensure accurate crimping force

- Clean and lubricate the tool as per manufacturer’s instructions

- Store the tool in a dry and clean environment

Troubleshooting Common Issues with Circumferential Crimping Tools

Despite proper usage and maintenance, issues with circumferential crimping tools can occur. Here are some common problems and troubleshooting steps:

- Loose crimp:Check the crimping force, die alignment, and wire preparation

- Over-crimping:Adjust the crimping force or use a smaller die

- Damaged dies:Replace the damaged dies

- Tool malfunction:Contact the manufacturer for repair or replacement

Helpful Answers: A Circumferential Crimping Tool Is Used For_____.

What are the different types of circumferential crimping tools?

Circumferential crimping tools come in various types, including manual, hydraulic, and pneumatic tools. Each type offers unique advantages depending on the application and required crimping force.

What are the benefits of using circumferential crimping tools?

Circumferential crimping tools provide numerous benefits, such as improved electrical conductivity, reduced risk of corrosion, enhanced mechanical strength, increased efficiency, and reliability.

What factors should be considered when choosing a circumferential crimping tool?

When selecting a circumferential crimping tool, consider factors such as capacity, crimping force, ergonomic design, compatibility with connectors, and the specific application requirements.